Different operating modes and device configurations enable microsonic sensors to be used in all conceivable automation applications.

DIN EN 60947-5-2 Low-voltage switchgear and control gear: control circuit devices and switching elements; proximity switches

DIN EN 61000-4-2 Electromagnetic compatibility: testing and measurement techniques; electrostatic discharge immunity test

DIN EN 61000-4-3 Electromagnetic compatibility: testing and measurement techniques; radiated, radio-frequency electromagnetic field immunity test

DIN EN 61000-4-4 Electromagnetic compatibility: testing and measurement techniques; electrical transients/burst immunity test

EN 55011 Limits and methods of measurement of radio disturbance characteristics of ISM radio-frequency equipment

IEC 60068-2-6 Environmental testing – test Fc: vibration

IEC 60068-2-27 Environmental testing – test Ea and guidance: shock

EN 60529 Degrees of protection provided by closures (IP code)

|

People detection

If the task is to detect the presence of persons, you are recommended to choose a sensor with an operating range well in excess of the required scanning distance. The greater the operating range of a sensor, the lower is its ultrasonic frequency. And the lower the ultrasonic frequency, the easier it is to detect absorbent clothing materials such as wool or corduroy. |

|

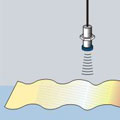

Monitoring foil

Film and foil in packaging machines is very easily monitored with a sensor from the pico range. If the material does not lie flat, it is advisable to operate the sensor as a two-way or reflective barrier because this operating mode also works reliably when the sonic beam is deflected away by the waves in the material. |

|

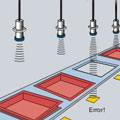

Monitoring of trays

A solution with the sensor operating as a two-way or reflective barrier should always be preferred when the object to be scanned absorbs the sound waves or, due to its shape or position in the tray, deflects the sound waves away. In this situation an additional reflector is positioned behind the actual object to be scanned. An ultrasonic sensor with switched output and operating in window mode emits a signal as soon as the object obscures the reflector. |

|

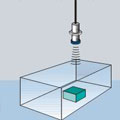

Presence detection

Sensors with a switched output, e.g. from the mic range can be employed depending on the size of the box or container. The mic+25/D/TC, mic+35/D/TC and mic+130/D/TC are available for scanning in small boxes. With larger containers you are recommended to use a mic+340/D/TC or a mic+600/D/TC. If the box or container is to be scanned by several sensors, the use of a sensor from the wms range in conjunction with a separate wms controller is recommended. |

|

Loop control

In this case an ultrasonic sensor with analogue output scans from above into the loop and adjusts the material feed depending on the size of the loop. If a loop of material tends to swing sideways, the sound waves are very easily deflected away when scanning from above. In such cases it is recommended to scan the loop from below, as shown in the diagram. |

|

Checking diameter

The diameter of a roll or coil of material can be detected by an ultrasonic sensor with analogue output and the drive adjusted or brake applied accordingly. For small diameters this is a typical application for a mic-31/IU/HV/M30, and for diameters up to 2.5 m a mic-101/IU/HV/M30. |

|

Stacking height control

Whether wooden boards, panes of glass, sheets of paper or coloured plastic panels, ultrasonic sensors are ideal for detecting the height of a stack of material with great accuracy. |

|

Ultrasonic barrier

It is easy to set up a two-way or reflective barrier using an ultrasonic sensor operating in window mode. To do this, a permanent reflector is positioned behind the objects to be scanned. When an object obscures the reflector, a switching signal is generated. |

|

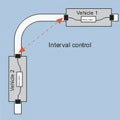

Interval control

The trans-o-prox enables active interval control between two vehicles. To do this, each vehicle is fitted with one ultrasonic sensor at the front and another at the rear. The vehicle travelling in front then responds to the signals of the vehicle behind. |

|

Installation for a foil extruder

The wms-4/4I controller with four 4-20 mA analogue outputs is ideal for controlling the diameter on a foil extruder. |